The most minute shavings and impurities are produced when grinding metallic components. These have to removed with certainty after grinding. The process chosen for this purpose is industrial parts cleaning. Silberhorn Maschinenbau GmbH will be demonstrating how this process can be integrated highly efficiently, effectively and economically at the GrindingHub in Stuttgart this year. The specialists in cleaning parts are presenting the Silberhorn MWS 4135 from 14 to 17 May in Hall 10, Stall D40. The Multi Washing System is perfect for meeting the requirements in modern grinding technology.

Ticket code: VISITSILBERHORN

Secure your ticket at grindinghub.de/en using the code

>>> VISITSILBERHORN <<<!

After the successful premier in the year 2022, the event hosts are expecting thousands of professional visitors once again at the GrindingHub 2024. Thus, the Trade Fair event in Stuttgart is developing into an international hub for grinding technology and super-finishing. The Exhibition Centre is displaying grinding machines, tool grinding machines and grinding agents or abrasives. Almost all users of grinding technology have one aspect in common: Before you can sell your products, they have to be cleaned and cleared of adhesions of oily substances as well as shavings and residues from the grinding process.

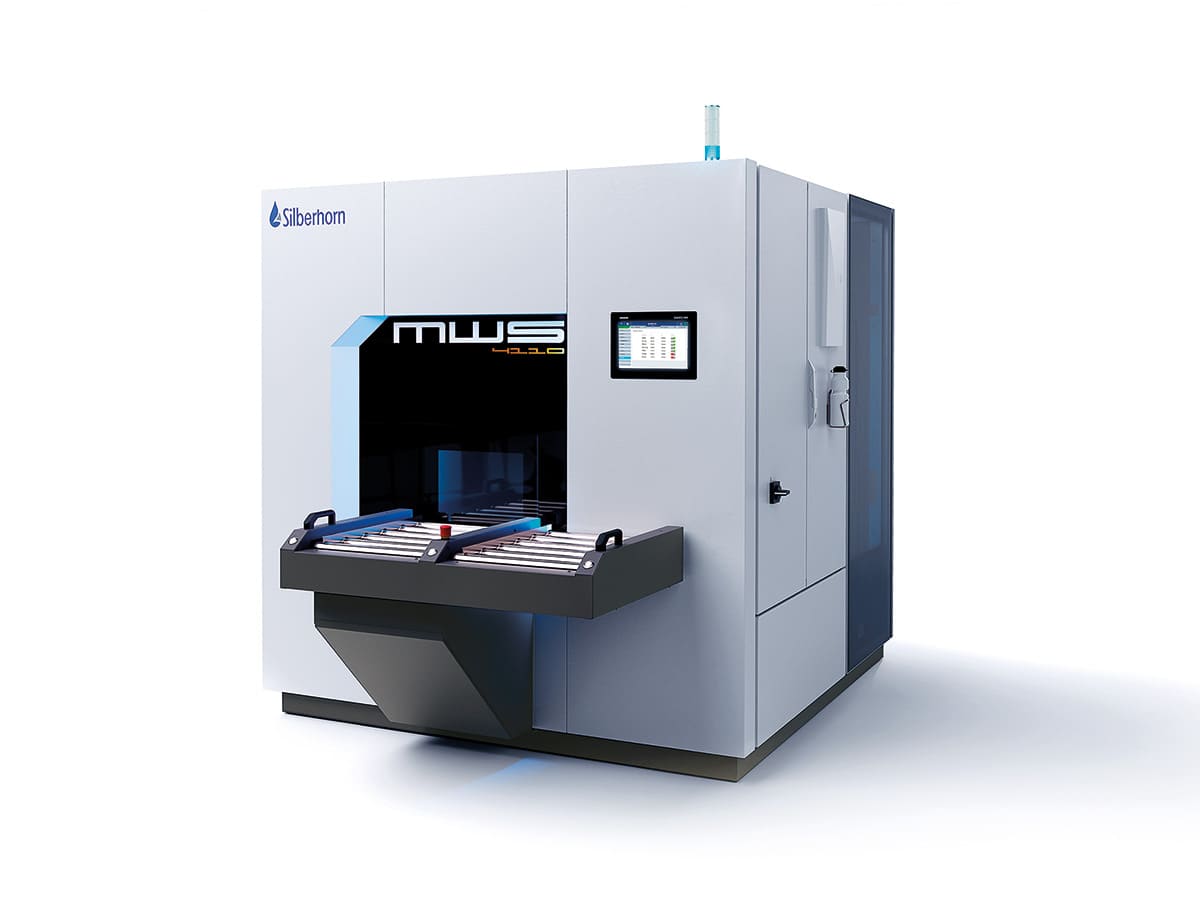

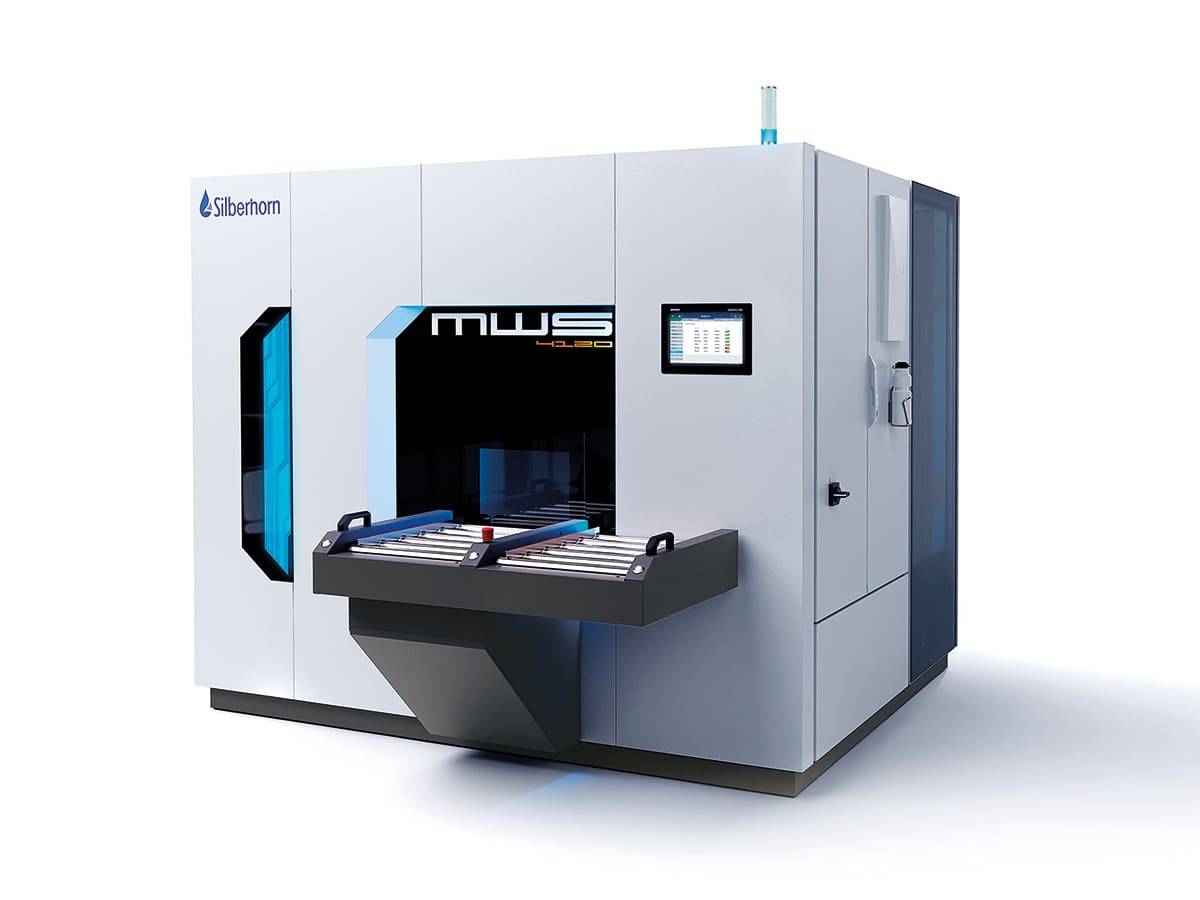

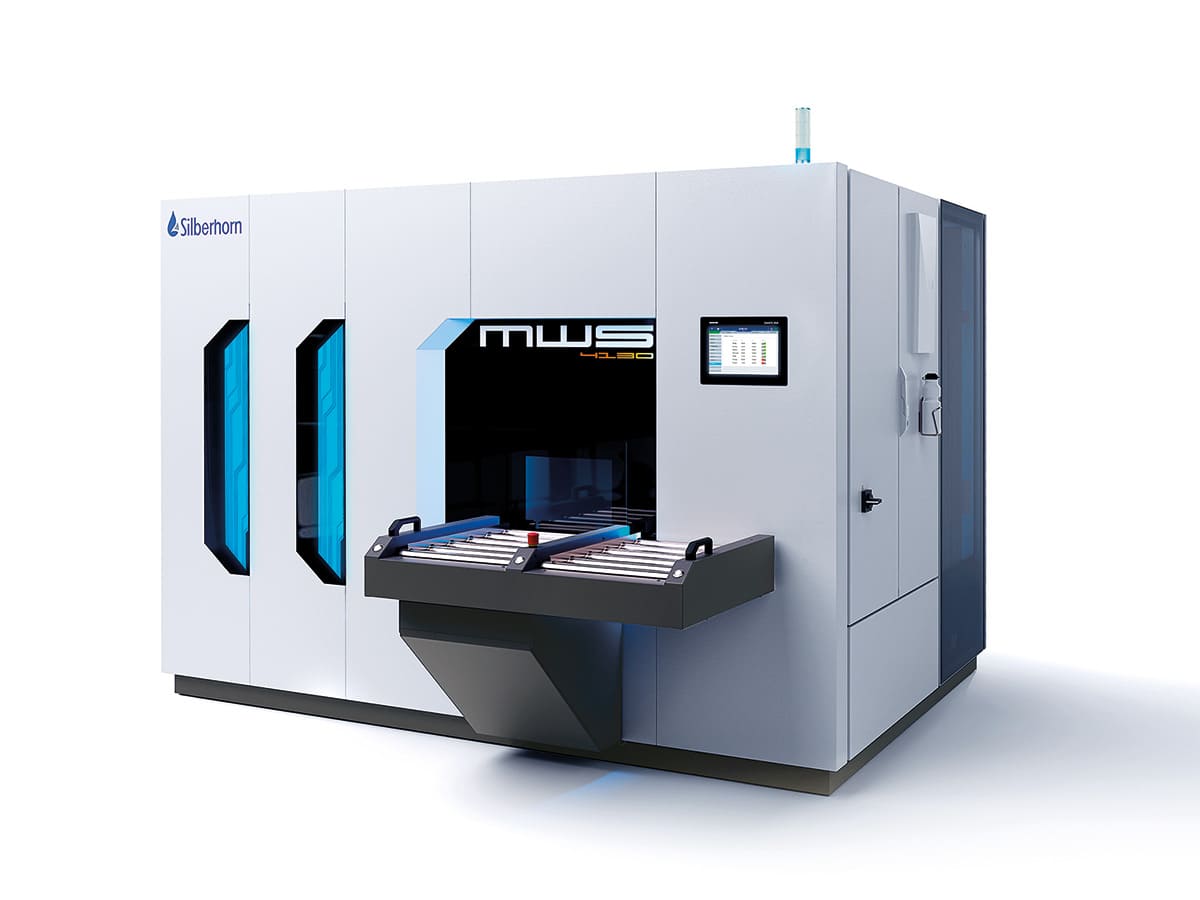

This takes place with the help of systems for industrial cleaning of parts using water as the cleaning medium. Installing such a system was associated in most cases with great effort and high investments costs so far. How this can be done in another way is what the parts cleaning experts from Silberhorn are demonstrating at the Grinding Hub this year. The Bavarians are arriving at the young professional trade fair with the Silberhorn MWS 4135.

The speciality with the new Multi Washing System (MWS): The innovative single-chamber cleaning system is manufactured with great efficiency on a mass manufacturing scale, and it can be supplied within a matter of weeks and it arrives - completely in line with the motto “Plug and Clean” - in completely assembled condition at the client's premises. Moreover, the Silberhorn MWS is so compact that it can fit into an overseas shipping container without any problem. This saves transportation costs and ensures quick and, thus, cost-effective commissioning of the system.

Equally extraordinary is the modular design and construction of the Silberhorn MWS right from the word "Go”. The cleaning system is available optionally as a 1-tank, 2-tank or 3-tank system, and can be customised perfectly to meet specific cleaning requirements thanks to the large number of options available.

Select highlights of the Silberhorn MWS 4135

Variable to the maximum extent – right from the time of loading

Whether as a stand-alone solution with manual loading, linked and integrated via motorised driven roller conveyors in the production line or fully automatic with robotic loading: With the Silberhorn MWS, users have the freedom of choice right from the time of loading the system. A principle that is both appealing and attractive. This is achieved with the help of about 40 optional equipment add-ons and extras in addition to the comprehensive basic configuration.

Cleaning chamber with 4-way swivel unit

The heart of the Silberhorn MWS is the cleaning chamber. It can be fitted with a 4-way swivel unit developed by the in-house team for the system. The principle of operation: A central, externally placed drive moves units fitted with 4 nozzles in the cleaning chamber. The swivel angle is +/- 30˚. Simultaneously, the basket (or material carrier) with the components rotates freely in the chamber. In this way, the water jet impinges on the components with constantly varying angles. This ensures excellent cleaning, even in case of components with complex geometries or undercuts and back tapers.

One chamber, four types of cleaning

Apropos maximum cleanliness: In order to achieve this, the Silberhorn MWS masters up to four different types of cleaning. The range goes from the classical spray cleaning to pressure and flood cleaning and right up to ultrasound cleaning in optionally two different frequency ranges.

Sustainable and energy-efficient

The Silberhorn MWS combines top class cleaning performance with consistent sustainability and energy efficiency. This is achieved with the help of technologies such as the integrated air humidity sensor in the cleaning chamber. This sensor measures the residual air humidity continuously and ends the drying process in the system as soon as a previously defined degree of air humidity is reached. This is supplemented by efficiency technologies such as the mass-manufactured, integrated bypass filtration. This increases the bath standing times, reduces the consumption of cleaning agents and enhances machine availability.

The Trade Fair presence: unique and compact

A parts cleaning system ingeniously designed from A to Z that can easily fit into an overseas shipping container? Silberhorn is making the idea of the overseas shipping container a unique selling point by demonstrating it. The parts cleaning experts are using an overseas shipping container as the Trade Fair stand. Surprisingly: The container does not only have place to accommodate the Silberhorn MWS ready for demonstrations, but also has a small trade fair bar with coffee, drinks and an inviting ambience for discussions with the experts.

Also on board: The piece-based cleaning specialists from Silberhorn

How parts manufacturers bridge the short time until commissioning of the Silberhorn MWS or absorb the capacity bottlenecks of their own parts cleaning facility? At best in cooperation with the piece-based cleaning specialists from Silberhorn. They accept components in terms of truckloads and clean them professionally at the location in Lupburg in the Bavarian Upper Palatinate. There are several high-performance parts cleaning systems available for this purpose. The team manages the logistics from acceptance of the parts up to their return to the production line of the customers on request.

Benefits for piece-based cleaning customers:

- Outsourcing the industrial parts cleaning to a team of experts

- No investment in systems, no personnel costs of your own

- High level of flexibility and reliability

- Industrial parts cleaning as needed – somewhat like with utilisation peaks

- Silberhorn ensures compliance with the technical cleanliness in its own in-house test laboratory