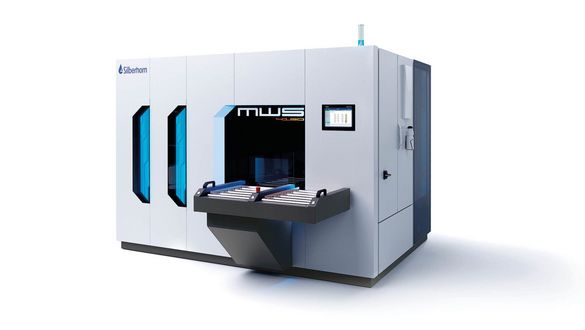

Silberhorn Multijet LC: For tough cleaning tasks without a lot of frills

This small but mighty machine was designed for the toughest jobs:

- for smaller companies that do not necessarily manufacture in series

- for companies that need to clean components but do not have ultra-high standards of cleanliness

- for anyone who has to clean one component or another - and sometimes a tool too

- for turners, millers, metalworkers and many more

The concept:

A single-chamber cleaning system that focuses on the essentials. Easy to operate, simple in design, customizable to…