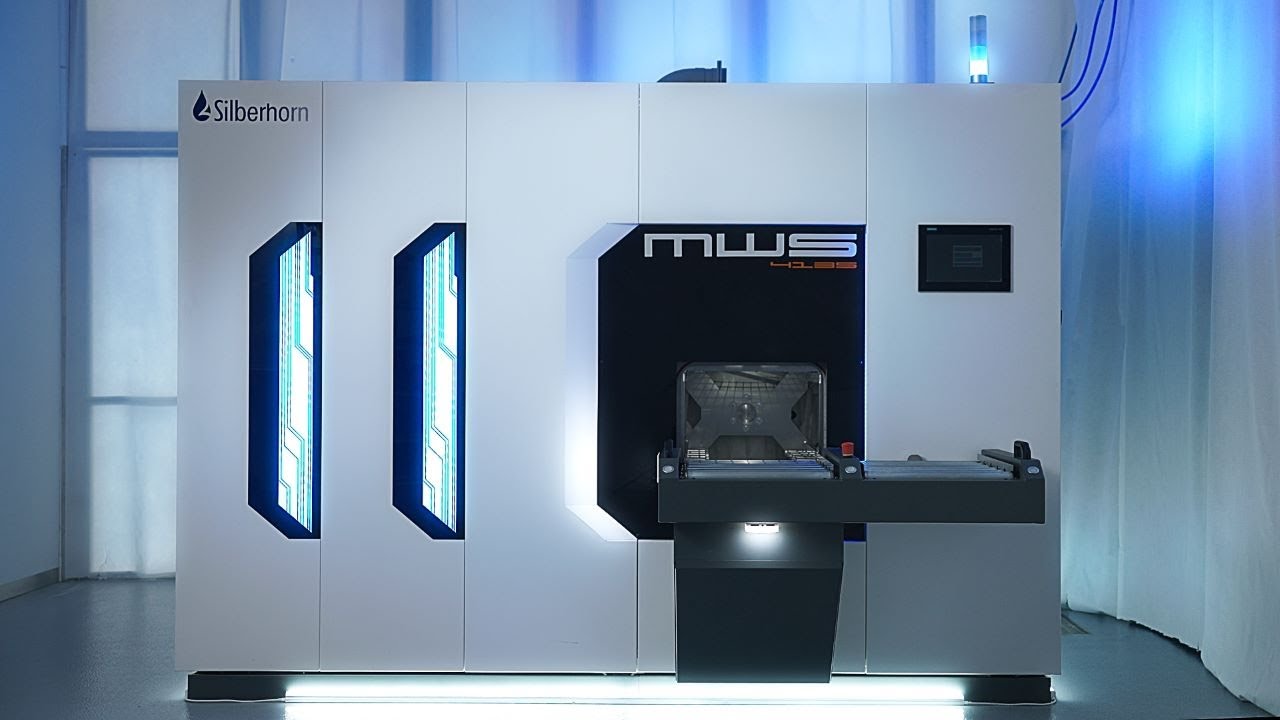

The new Multi Washing System (MWS) cleans your components with consistently high quality: while taking up minimal space and boasting unbeatably low overall costs. In short, the Silberhorn MWS is revolutionising water-based industrial parts cleaning. This world first comes equipped with technology you would usually have to order as an add-on. Plus, you get unprecedented variability: with Silberhorn you can choose and order the MWS as a one, two or three-tank system according to your needs.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

When you click the play button, content from the YouTube video platform is loaded. Cookies can be saved in the process.

Whether you want them clean or microscopically pure, whether they are steel, titanium or power electronics: the Silberhorn MWS cleans components of all types and meets the highest standards across industries.

Speed, cost, versatility: the MWS can handle the requirements of machining operations of all sizes and specialisations.

Equipped with the optional EMC chamber, the Silberhorn MWS makes sure medical components are clean and germ-free at a microscopic level.

Integrated conductance monitoring, purged rinsing and cleaning tray for electrotechnical components? Everything is possible with the Silberhorn MWS.

The MWS is available as a one, two or three-tank system.

The four-header swivel spray unit developed by Silberhorn guarantees optimum cleaning results.

The loading table of the MWS is installed at a comfortable height of 85 cm.

Thanks to intelligent cycle assembly, the Silberhorn MWS has a incredibly fast delivery time of about 8 weeks (without interlinking).

With its extremely compact design, even the largest Silberhorn MWS fits in a 20-foot container. Footprint of each version:

Spray cleaning: with high kinetic energy; ideal for less complex components and standard cleanliness requirements.

Pressure flood washing: the right choice for full wash trays and complex components. Achieves excellent results.

Scoop flood washing: optimised for components with complex internal geometries and high cleaning requirements. The cleaning fluid goes in and out of the components at each turn. Contaminants are rinsed away.

Ultrasonic cleaning: the ultrasonic waves, which vibrate in two frequency ranges (25 kHz or dual frequency 25/75 kHz), support the entire cleaning spectrum, from pre-cleaning to precision cleaning.

Do you have any questions about maintenance, programming or technical add-ons for your MWS? We are happy to advise you! Just call the Silberhorn hotline.

The Silberhorn MWS is ready for Industry 4.0 from the word go! All of the necessary connections and interfaces are built in. This allows our service engineers to access your MWS via remote maintenance upon request – right away and without an expensive call-out charge.

Through virtual webinars or in-person training sessions at your premises, we offer tailored training so that you and your team can get the most out of your MWS.

Which cleaning process is the most effective for your cleanliness requirements? Let’s find out together: in Silberhorn’s own technical centre and test lab.

| MWS 4110 | MWS 4120 | MWS 4125 | MWS 4130 | MWS 4135 | |

| APPLICATION | |||||

| Interstage cleaning | |||||

| Demanding cleaning | |||||

| Precision cleaning (high-end) | |||||

| Special electrical/medical cleaning (EMC) | |||||

| CLEANING | |||||

| Spray cleaning | |||||

| Flood washing | |||||

| Scoop flood washing | |||||

| Targeted cleaning | |||||

| Interstage rinsing | |||||

| Deionised interstage rinsing | |||||

| Recycled interstage rinsing | |||||

| 4-header spray unit (fixed) | |||||

| 4-header swivel spray unit | |||||

| Filtration for demanding cleaning | |||||

| Filtration for precision cleaning | |||||

| Ultrasonic cleaning (25 kHz) | |||||

| Dual-frequency ultrasonic cleaning (25/75 kHz) | |||||

| DRYING | |||||

| Compressed air pulsing | |||||

| Targeted drying | |||||

| Combined pulse and hot-air drying | |||||

| Hot-air drying with air humidity control | |||||

| Vacuum drying in process cabin | |||||

| External vacuum drying (with loading conveyor only) | |||||

| TECHNICAL DATA | |||||

| Dimensions in mm (W x H x D) | 2160 x 2150 x 2200 | 2600 x 2150 x 2200 | 2600 x 2150 x 2200 | 3100 x 2150 x 2200 | 3100 x 2150 x 2200 |

| Tray dimensions in mm (W x H x D) | 670 x 480 x 300 | 670 x 480 x 300 | 670 x 480 x 300 | 670 x 480 x 300 | 670 x 480 x 300 |

| Alternative tray dimensions in mm (W x H x D) | 600 x 400 x 300 | 600 x 400 x 300 | 600 x 400 x 300 | 600 x 400 x 300 | 600 x 400 x300 |

| Other tray dimensions | upon request | upon request | upon request | upon request | upon request |

| Weight per batch in kg | 150 | 150 | 150 | 150 | 150 |

| Weight of system (in tonnes) | from 1,7 | from 2 | from 2,2 | from 2,4 | from 2,6 |

| Loading height in mm | 850 | 850 | 850 | 850 | 850 |

| Tank volume in litres | 450 | 450 + 340 | 450 + 340 | 450 + 340 + 340 | 450 + 340 + 340 |

| Electrical connected load | from 15 KW | from 20 KW | from 40 KW | from 30 KW | from 50 KW |

| SOFTWARE / HMI | |||||

| Preset programs (quantity) | 3 | 3 | 3 | 3 | 3 |

| Freely selectable programs (quantity) | 17 | 17 | 17 | 17 | 17 |

| Special cleaning programs (quantity) | 0 | 0 | up to 17 | 0 | up to 17 |

| Remote maintenance | |||||

| Analysis / business intelligence | |||||

| Conductance analysis (via probe) | |||||

| Gesture control (from 2023) | |||||

Sebastian Töpfl

S.Toepfl(at)maschinenbau-silberhorn.de

Tel: +49 (0) 9492 9425-4338